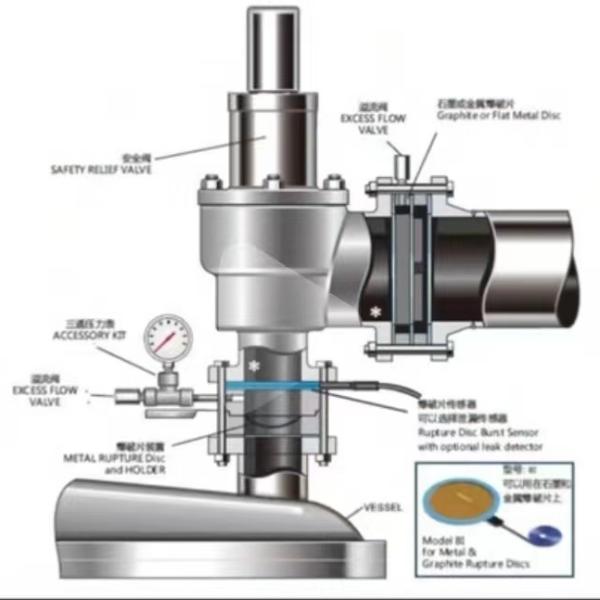

Introduction of rupture disc kit zero relief device:

When the rupture disc and the safety relief valve for rupture disk are connected in series, a rupture disc kit-zero relief device must be used, which consists of a pressure gauge, a relief valve, a tee, a pipe, etc. It is used between the safety relief valve for rupture disk and the rupture disc, or other confined spaces where back pressure needs to be cleared. A relief valve and a pressure gauge must be installed between the rupture disc and the safety relief valve for rupture disk to ensure that the rupture disc bursts correctly. When the rupture disc works normally, the pressure between the holder and the safety valve is connected to the atmosphere to ensure that the cavity pressure is zero and prevent the pressure accumulation in the space.

Working principle of rupture disc kit zero relief device:

1. The rupture disc accessories bleeder consists of an adjustable valve that can control the cross-sectional area of the channel through which the fluid passes. When the valve is completely closed, the fluid cannot pass, and the pressure and flow are zero.

2. When the rupture disc accessories valve begins to open, the cross-sectional area of the channel increases, allowing the fluid to pass. As the valve opens further, the cross-sectional area of the channel continues to increase, and the speed of the fluid passing through also increases, thereby increasing the kinetic energy of the fluid.

3. As the rupture disc accessories valve opens further, the cross-sectional area of the channel continues to increase, and the speed of the fluid passing through continues to increase, but the resistance also decreases. When the valve is fully opened, the cross-sectional area of the channel is the largest, the fluid can pass freely, and the pressure and flow rate reach the maximum value.

4. Therefore, by adjusting the opening of therupture disc accessories valve, the pressure and flow rate of the fluid passing through the channel can be controlled. When the valve is adjusted to the appropriate position, the pressure and flow rate can be reduced to zero, achieving the effect of zero leakage.

Benefits of connecting the rupture disk in series with the safety relief valve for rupture disk:

1. Rupture disk with safety relief valve can achieve zero leakage and can effectively isolate the medium, such as toxic, harmful or relatively expensive media.

2. Reduce the material requirements of the safety valve, thereby reducing the use cost of the rupture disk with safety relief valve.

3. Extend the use time of the rupture disk with safety relief valve.

Application areas of rupture disc kit zero leakage device:

Pharmaceutical industry, metallurgical industry, food processing, petroleum industry, coal energy, environmental protection industry and chemical industry

About our rupture disc accessories:

We always adhere to the development concept of "focus, integrity, safety and efficiency" to serve the market and users. We have always focused on the research and development of rupture disc kits, using integrity to build quality, using excellent rupture disc kit to win the market, and putting the safety of user systems first. XinGuang Aerospace looks forward to working with new and old partners to create a better rupture disc kit future!