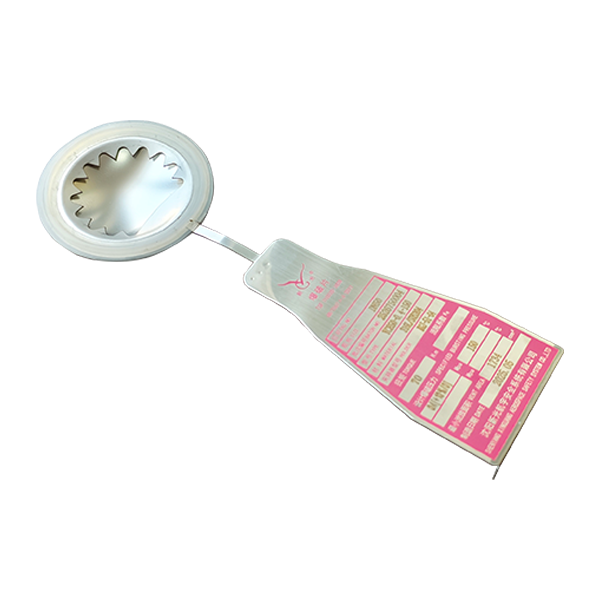

Introduction of YCE reverse arch bursting disc:

YCE reverse arch bursting disc has an annular groove processed on the R outer side of the clamping diameter, and an alligator tooth reinforcement ring is added on the outlet side of the bursting disc. The bursting disc is unstable and flipped. Under the action of the unstable pressure, it opens along the annular groove with the help of the crocodile tooth tip to achieve the purpose of discharge. This type of blasting is equipped with a KGJ clamp.

Features of YCE reverse arch bursting disc:

1. YCE reverse arch bursting disc adopts a fragment-free design.

2. YCE reverse arch bursting disc has strong fatigue resistance and can be used in working conditions with pulsating pressure.

3. YCE reverse arch bursting disc can withstand a complete vacuum state without a vacuum bracket.

4. YCE reverse arch groove crocodile tooth type bursting disc can be used for gas media.

5. The maximum working pressure of YCE reverse arch groove crocodile tooth type bursting disc can reach 90% of the minimum allowable bursting pressure.

Precautions:

1. The material of the crocodile tooth of YCE reverse arch groove crocodile tooth type bursting disc is generally austenitic stainless steel.

2. If it needs to be coated with polytetrafluoroethylene or polypropylene, please pay attention to its use temperature.

Manufacturing parameters:

Size range: DN20—DN100.

Pressure range: 0.1MPA—1.0MPA.

Product maintenance:

1. Regularly check the appearance and observe whether there is rust, pitting or chemical corrosion on the surface of the bursting disc, check whether there are scratches, dents or deformation, and avoid external forces affecting the accuracy of the bursting pressure, at least once a month.

2. Use a soft cloth or low-pressure airflow to remove dust and oil on the surface. Do not use sharp tools or strong acid/alkali for cleaning to avoid damaging the crocodile groove structure.

3. If the bursting disc is linked to the safety valve, ensure that the downstream pipeline of the bursting disc is unobstructed to avoid back pressure affecting the performance.

About us:

Shenyang Xingguang Aerospace Safety System Co., Ltd. was established in 1959. It is the first professional manufacturer of bursting disc safety devices integrating R&D, production, sales and service after the founding of New China. In the 60 years since its establishment, it has always adhered to high standards and high requirements, accurately controlled design plans and material selection, and now has more than 30 independent intellectual property rights. The company always adheres to the development concept of "focus, integrity, safety and efficiency" to serve the market and users. It focuses on the development and research of bursting disc devices and firmly believes in winning with quality.