Introduction of product:

Reverse arch bursting disc is a safety pressure relief device for pressure vessels and equipment. The core components of the Reverse arch bursting disc are the reverse arch bursting disc and the supporting gripper. Reverse buckling type bursting disc is used to quickly release the pressure through the rapid flipping and ejection of the bursting disc when the system pressure exceeds the set value, thereby protecting the safety of equipment and personnel.

Features of product:

1. Reverse buckling type bursting disc has strong fatigue resistance and is suitable for pulsating pressure occasions.

2. Reverse buckling type bursting disc can be applied to the protection of large-caliber and low-voltage systems.

3. Reverse buckling type bursting disc can withstand vacuum back pressure, and the back pressure bracket needs to be increased. Its discharge area is about 50% of the nominal diameter.

4. Reverse buckling type bursting disc can be applied to gaseous media.

5. The maximum working pressure of the clamping type bursting disc can reach 90% of the specified bursting pressure.

6. The rupture disc and gripper of the clamping type bursting disc must be assembled by the manufacturer and shipped out of the factory uniformly.

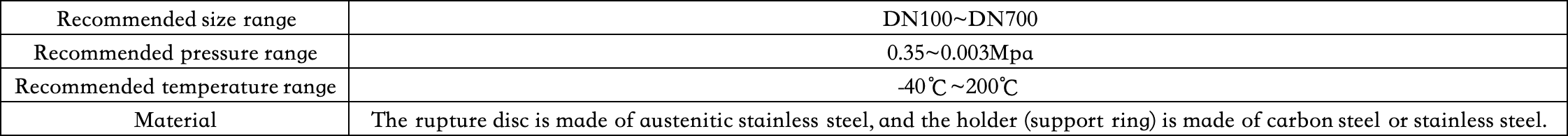

Parameters of product:

Maintenance of product:

1. Conduct regular visual inspections of the clamping type bursting disc to check the surface for corrosion, cracks, deformation or mechanical damage.

2. Check the sealing of the clamping type bursting disc to observe whether there is leakage between the rupture disc and the gripper.

3. Remove the residues of process media (such as fouling and crystallization) on the rupture disc and gripper, avoid corrosion or clogging, use a soft cloth or non-metallic brush to clean, and disable sharp tools from scratching.

4. If the medium is corrosive, check whether the material of the rupture disc still meets the requirements. In a humid environment, apply anti-rust grease to the gripper bolts.

5. When the surface of the clamping type bursting disc is damaged, severely corroded, or the seal fails, it should be replaced immediately.

About us:

Shenyang Xinguang Aerospace Safety Systems Co., Ltd. is the first professional manufacturer of rupture disc safety devices integrating R&D, production, sales and service after the establishment of New China. The company originated in 1959 and was born in Xinguang Aerospace Group. With deep technical accumulation and excellent innovation strength, the company obtained the rupture disc system production license issued by the Ministry of Labor in 1986, and was recognized as a high-tech enterprise by the Provincial Department of Science and Technology in 2000.