Clamping force is the core control parameter in the installation process of rupture disc, which directly determines many key aspects of the performance of rupture disc. Because of the differences in structural design and force principle of different types of rupture disc, there are obvious differences in the sensitivity of clamping force and the affected performance. If improperly controlled, it may cause safety hazards such as deviation of burst pressure and seal failure. In this article, I will bring you a system analysis:

General effect of clamping force on the performance of rupture disc:

1. Burst pressure accuracy:

When the clamping force is insufficient, the edge restraint strength of the rupture disc weakens, and the effective pressure bearing area passively increases, resulting in the actual burst pressure generally lower than the design set value. Excessive clamping force will cause rupture disc to produce pre-compressive stress, and additional pressure is required to offset the force to trigger blasting, causing the blasting pressure to increase. The measured data show that improper clamping force control may cause the burst pressure deviation to reach ±10% or even higher of the set value. When the deviation exceeds the safety threshold, rupture disc will completely lose the protection function of the equipment.

2. Sealing performance:

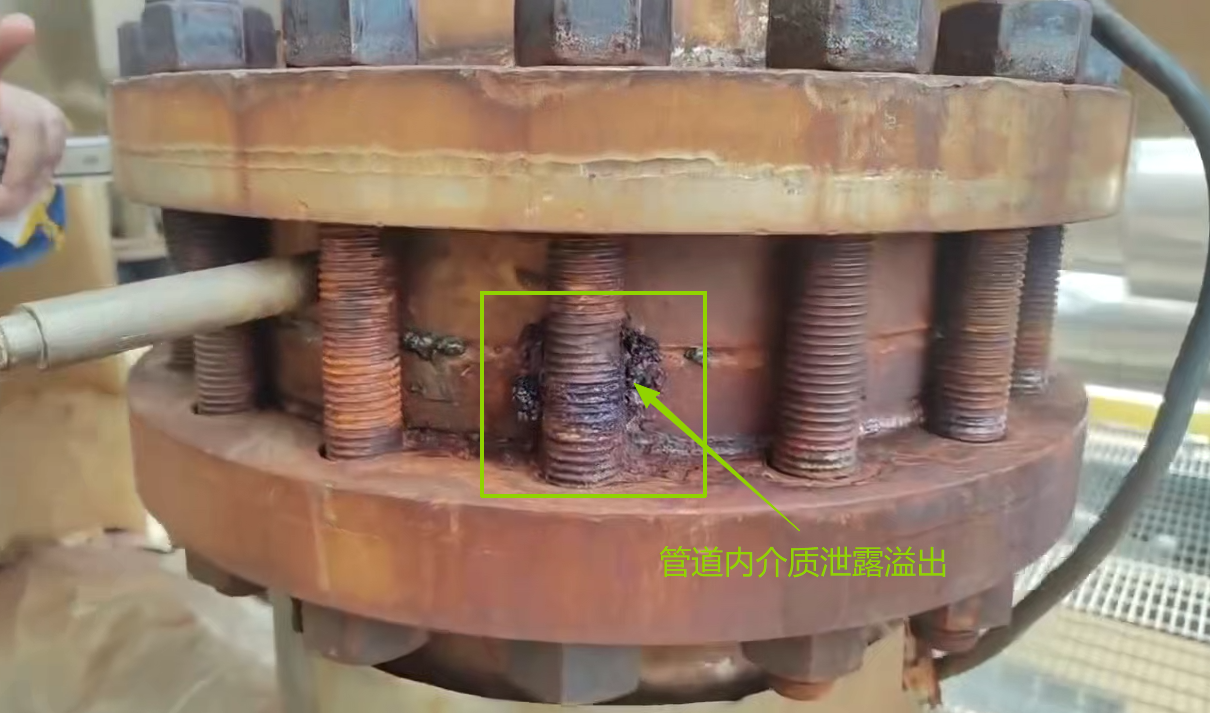

Seal failure is a common risk of improper clamping force control. When the clamping force is insufficient, the contact surface between the rupture disc and the flange cannot form an effective seal. Especially in systems that transport toxic, flammable or corrosive media, media leakage is very prone, which will not only cause economic losses, but may also cause safety accidents and violate relevant regulations such as the "Pressure Vessel Safety Technical Supervision Regulations". Conversely, excessive clamping force may crush sealing elements such as O-rings and gaskets, or directly damage the sealing structure at the edge of the rupture disc, destroy the sealing of the contact surface, and cause leakage problems.

3. Action reliability:

Insufficient clamping force will cause the rupture disc to rupture incomplete, unable to form a sufficient discharge area, and even produce debris to block the discharge port, affecting the efficiency of medium discharge. For the anti-arch rupture disc, it may also fail to slide out as a whole, completely losing the ability to discharge. Excessive clamping force will cause stress concentration at the edge of the rupture disc, causing rupture in unexpected locations, such as edge tearing, etc., causing the discharge path to deviate from the design expectation, weakening the discharge efficiency, and unable to reduce the pressure in the equipment in time, thereby threatening system safety.

As a company specializing in the field of rupture disc safety devices, we understand the key impact of clamping force on the performance of rupture disc, and we also understand the core needs of B-side customers for "safe and reliable, controllable cost, and worry-free service". All of our rupture discs have been tested for the adaptability of clamping force, the optimal clamping force range is preset according to different working conditions, and accurate torque control parameters are provided in the product manual. At the same time, the edge of the rupture disc adopts a special reinforced structure, which can effectively buffer the impact of clamping force fluctuations, greatly reduce the performance risks caused by installation and operation errors, and reduce your later maintenance costs. If you now need a batch of rupture disc products with stronger adaptability and higher reliability. Please contact us, we will use technological innovation and quality service to satisfy you.