Bursting disc is actually a disposable pressure relief safety device. The main purpose of bursting disc is to provide reliable overpressure protection for industrial equipment and piping systems. When the pressure in the system rises rapidly for various reasons and reaches the predetermined burst pressure of the bursting disc, the bursting disc will quickly rupture, releasing the high-pressure medium in the system, and reducing the pressure to a safe range, in order to prevent the equipment from exploding due to overpressure, leakage and other catastrophic accidents.

From the perspective of industrial safety, the existence of bursting disc is very meaningful. Bursting disc not only meets the requirements of relevant national safety regulations and standards, but also takes the initiative to take responsibility for safe production. By installing a reliable bursting disc, enterprises can reduce the probability of safety accidents, ensure the integrity of production equipment, and reduce the downtime and maintenance time and cost caused by equipment damage. At the same time, for production processes that may involve toxic, harmful, flammable and explosive media, the timely pressure relief of bursting disc can effectively prevent environmental pollution and secondary disasters caused by media leakage, and maintain the company's good social image and reputation.

However, not all bursting discs can truly meet the strict requirements of enterprises for security protection. The quality of bursting discs on the market is uneven, and bursting discs of different materials, structures, and manufacturing processes have large differences in performance and applicable scenarios. This requires companies to carefully choose suppliers with professional qualifications and extensive experience when purchasing bursting disc.

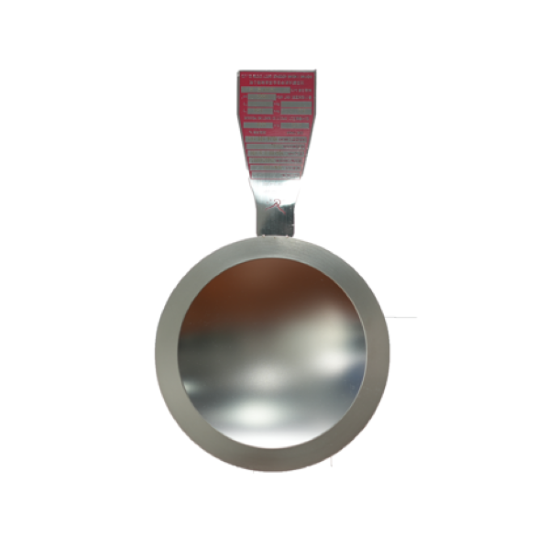

And our bursting disc is manufactured based on a comprehensive understanding of industrial safety needs and years of technical accumulation. In the selection of raw materials, we strictly screen high-quality metal and non-metallic materials, so that each piece of bursting disc has excellent corrosion resistance, fatigue resistance and stable blasting performance. In the production process, we adopt advanced processing technology and strict quality control system. From the inspection of raw materials into the factory to the inspection of finished products out of the factory, every link has undergone a number of strict controls to ensure that the performance indicators of the products can meet or exceed national standards and industry norms.

At the same time, our bursting disc has a high degree of customization ability, and can be tailored to design and manufacture the most suitable bursting disc solution for customers according to their different working conditions, such as pressure, temperature, and media characteristics. Whether it is a harsh environment with high temperature and high pressure, strong corrosion, or precision chemical production with extremely high blasting accuracy requirements, we can provide reliable products and professional technical support. In addition, we have established a perfect after-sales service system, which can provide customers with a full range of services from product selection to installation guidance, so that customers have no worries in the process of using it. We understand the importance of high-quality bursting disc for the safe production of enterprises and the safety of employees' lives. Please choose us and we will use the best products and services to satisfy you.