Introduction of Impervious graphite rupture discs:

Graphite rupture discs is a rupture-type pressure relief device used for the safety protection of pressure vessels. It has the characteristics of good sealing performance, fast reaction action, and strong corrosion resistance. It is suitable for working conditions where the reaction pressure rises sharply, the medium is easy to crystallize or is highly corrosive, and is widely used in low and atmospheric pressure vessels. The product is composed of bursting disc and holder. Other types of bursting discs can be connected in series, covering a wide range of size.

Advantages of Graphite Bursting Disc:

1.The temperature resistant rupture disc can be directly mounted between flanges or used with holders.

2.The temperature resistant rupture disc is suitable for highly corrosive media, with optional PTFE/FEP lining for enhanced chemical resistance.

3.The temperature resistant graphite rupture disc operates reliably within -50℃ to 200℃ in elevated temperature environments.

4.The temperature resistant rupture disc allows 80% of min burst pressure under steady conditions (60% with fluctuations) and requires perforated support for vacuum.

5.The temperature resistant graphite rupture disc fragments upon bursting and must not be installed in series with safety valves.

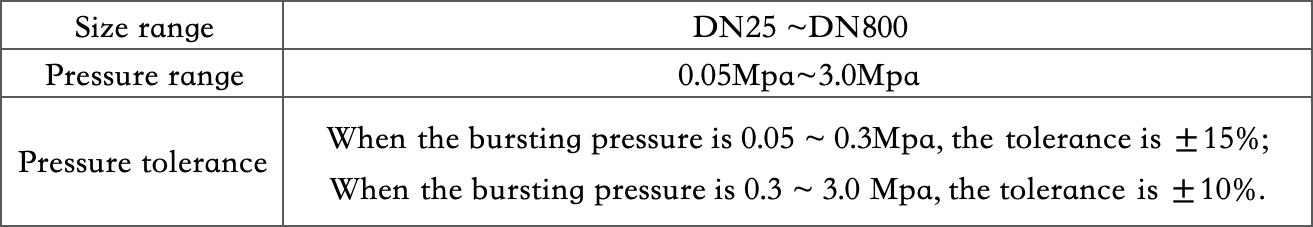

Processable pressure range of Graphite rupture discs:

Application of Impervious graphite rupture discs in graphite equipment protection:

1.Shell & tube/block-type graphite heat exchangers.

2.Graphite reactors (synthesis furnaces/absorption towers/reaction vessels).

3.Graphite piping systems & storage tanks.

Application of Impervious graphite rupture discs in industrial scenarios:

1.Chlorine/hydrochloric acid treatment system.

2.Wet process phosphoric acid production equipment.

3.Hydrogenation reaction equipment.

About services for Graphite disc burning disc:

Our company provides a quality guarantee period of 12 months (from the time the equipment is put into production and qualified) or 24 months (from the arrival of the equipment)(whichever comes first), during which the equipment with quality problems is repaired or replaced for free, and promises to respond to the failure within 24 hours. Outside the warranty period, it still provides 24-hour Incident Response Service, preferential paid maintenance and technical support (including installation guidance, document delivery, etc.), ensuring the stable operation of Temperature resistant graphite rupture disc for life.