Introduction of bursting discs for nuclear power:

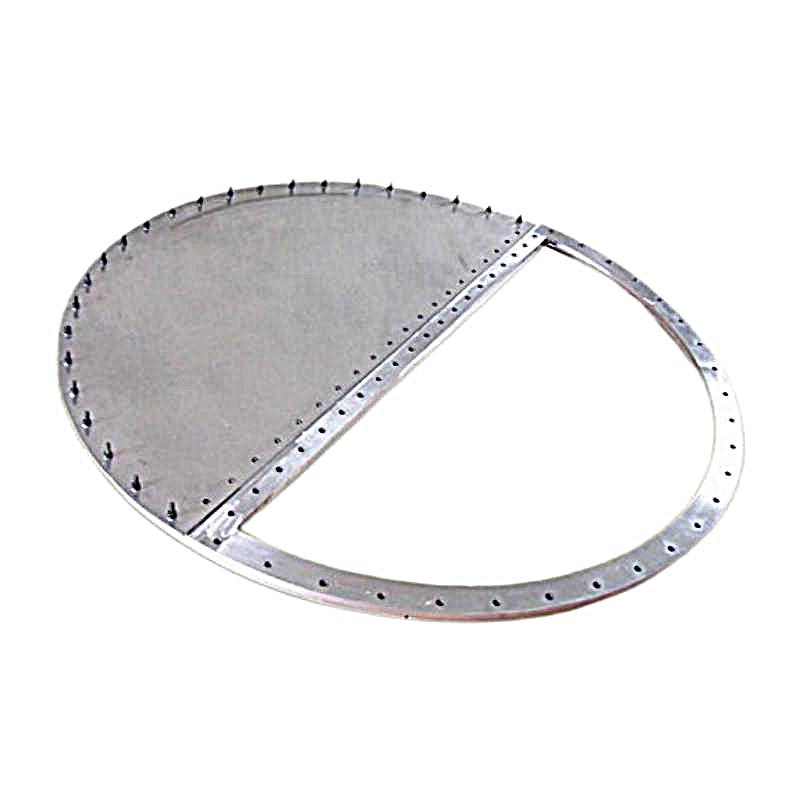

When the use limit specified in the design technical specification is exceeded during the operation of nuclear power pressure vessels, Overpressure blasting device bursting discs (safety valves, vacuum valves or non-reclosing pressure relief devices) are required to be installed. Overpressure blasting device bursting discs are sensitive to action and easy to maintain and install, and are widely used in nuclear power equipment. EVCOverpressure blasting device bursting discs are used to protect the integrity of the main air duct by ensuring that the bursting disc ruptures and releases pressure when the design peak pressure is reached when the design basis accident causes overpressure inside the main air duct. It adopts a semicircular design and is clamped by peripheral bolts.

Working mode of safety rupture discs:

Overpressure blasting device The working mode of bursting discs is similar to that of fuses in household electrical circuits. As a protective device for pressure relief boxes, safety rupture discs will quickly burst at specified pressure and temperature, triggered by the static pressure at the inlet, and release pressure by rupturing the pressure-bearing diaphragm, thereby ensuring the stability of the pressure relief box system and further maintaining the smooth operation of the entire nuclear power system. Safety rupture discs can ensure the safety of equipment and personnel under special circumstances at a lower cost.

Typical application scenarios of safety rupture discs in the nuclear power industry:

1. Reactor cooling system:

Safety rupture discs provide overpressure protection in the coolant system. They are generally located in certain parts of the containment or pressure boundary.

2. Containment ventilation system:

Rupture disc safety device in nuclear industry When overpressure is generated in the containment, the bursting disc acts as a backup safety valve to prevent structural damage.

3. Hydrogen control system:

Hydrogen may be generated due to damage to fuel rods and other reasons. Rupture disc safety device in nuclear industry can be used to prevent hydrogen accumulation from causing explosions.

4. Radioactive waste gas treatment system:

Rupture disc safety device in nuclear industry protects equipment and piping systems when dealing with gas overpressure.

Reverse acting rupture discs are widely used in the nuclear power industry, mainly because of its advantages:

1. Strong fatigue resistance: reverse acting rupture discs are suitable for systems with pressure fluctuations;

2. Accurate burst pressure: reverse acting rupture discs have high pressure control accuracy;

3. Reverse acting rupture discs are suitable for high temperature and high radiation environments;

4. Safe and reliable: The reverse arch design of reverse acting rupture discs has high structural stability before overpressure and is not prone to premature failure;

5. Reverse acting rupture discs can be used in parallel or in series with pressure relief valves as redundant or secondary safety devices.

High-end equipment, fine processing:

We have modern factories and automated precision processing equipment running at high speed to ensure the precision of each product. The company specially introduces advanced testing instruments to conduct strict pressure tests, sealing tests, and fatigue tests on products, so that the bursting discs for nuclear power are still stable, reliable and durable in extreme environments.