As an important overpressure safety relief device, reverse arch bursting disc has the characteristics of rapid response, good sealing, and wide applicable pressure range. This article allows us to understand the broad application fields of reverse arch bursting disc.

In the chemical industry, the production of reactors, storage tanks and other equipment often involves high temperature, high pressure and corrosive media. Reverse arch bursting disc can quickly respond to overpressure caused by uncontrolled chemical reactions, medium expansion, etc., and can effectively prevent equipment from exploding. For example, in the synthesis of ammonia, sulfuric acid manufacturing and other processes, reverse arch bursting disc can be used in conjunction with a safety valve as a secondary safety guarantee.

When oil extraction and refining are carried out in the petroleum field, drilling platforms, crude oil storage tanks, distillation towers and other equipment often face the risk of corrosive media such as high pressure, flammable and explosive, and hydrogen sulfide. Reverse arch bursting disc can be used to prevent overpressure caused by pipeline blockage, excessive heating, etc. It can be installed at the terminal of the oil pipeline or at the top of the storage tank, which can quickly release the pressure and reduce the hidden dangers of fire and explosion, and ensure the safe operation of the oil and gas treatment system.

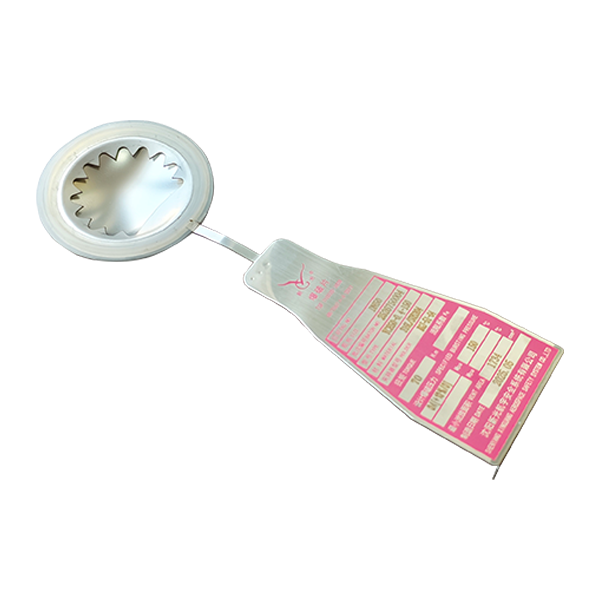

In the field of gas transportation, pipelines and equipment for transporting and storing natural gas, liquefied petroleum gas, industrial gases, etc. have high requirements for sealing and safety. Reverse arch bursting disc can cope with overpressure caused by rapid gas expansion. For example, at the distribution station of a long-distance natural gas pipeline and at the outlet of a gas compressor, crocodile tooth type bursting disc can release the pressure in time to prevent energy waste or poisoning caused by pipeline rupture and gas leakage. Risk of poisoning.

In the food and pharmaceutical fields, sterilization tanks and fermentation tanks in food processing, as well as reactors and sterile storage tanks in the pharmaceutical industry, need to operate in a sterile and clean environment, and the medium is basically steam, high-temperature water or liquid medicine. Crocodile tooth type bursting disc is made of inert materials such as stainless steel. It is not easy to contaminate the medium. It can meet hygiene requirements. At the same time, it can cope with overpressure conditions caused by improper pressure control during sterilization, and can ensure product quality and production safety.

In blast furnaces, converters, steel rolling equipment and gas recovery systems in the metallurgical field, high-temperature molten metals and combustible gases can easily cause overpressure risks. Crocodile tooth type bursting disc can be installed at important nodes of gas pipelines and pressure vessels, such as in the gas cabinet or compressor outlet of the gas purification system. Crocodile tooth type bursting disc can quickly release overpressure problems caused by gas accumulation and valve failure, which can prevent the equipment from exploding and allow the smelting process to run stably.

The crocodile tooth type bursting disc produced by Shenyang Xinguang Aerospace Safety Systems Co., Ltd. relies on the advantages of debris-free design, fatigue resistance and corrosion resistance, and is widely used in many industries. If you are looking for a high-quality safety venting device, you are welcome to ask us at any time, we look forward to your message!