In the production of dust industry, safety accidents caused by dust explosions, equipment overpressure, etc. often occur. These accidents will seriously affect personnel safety and production stability. As an important safety protection device, stainless steel rupture disk plays an important role in many scenarios of the dust industry and is one of the important equipment to ensure production safety.

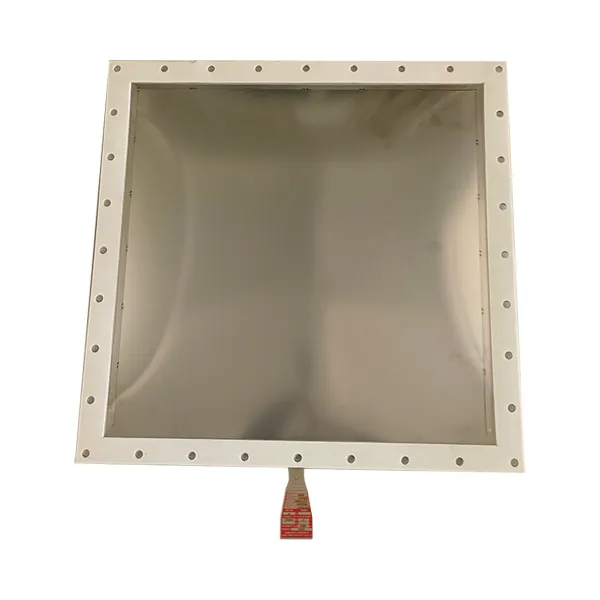

Stainless steel rupture disk is designed with a flat structure. This structure allows the rupture disc to have excellent compression resistance and accurate burst pressure control ability, which can quickly rupture when the internal pressure of the equipment exceeds the set safe value, release the pressure, and prevent the equipment from exploding or being damaged due to overpressure. At the same time, the material characteristics of stainless steel rupture disk also have good corrosion resistance, wear resistance and fatigue resistance, and can adapt to the complex and harsh working conditions of the dust industry.

In dust collection and treatment systems, stainless steel rupture disk is widely used. During the operation of equipment such as bag dust collectors and cyclone dust collectors, due to dust accumulation and clogging of filter bags, the internal pressure of the equipment can easily increase abnormally. At this time, if the pressure is not released in time, it may cause serious consequences such as rupture of the dust collector housing, dust leakage and even explosion. The rupture disc is installed on the housing or pipe of the dust collector. When the internal pressure reaches a preset blasting value, the rupture disc will burst instantly, quickly discharging high-pressure gas and dust, reducing the internal pressure of the equipment and preventing accidents.

The dust conveying pipeline system is an important link in the production of dust industry, and it is also a high-incidence area of abnormal pressure. During the pneumatic conveying process, if the dust concentration, air flow speed and other parameters in the pipeline fluctuate, the local pressure may be too high, causing pipeline rupture, dust leakage and other problems. stainless steel rupture disk is usually installed at key nodes of the pipeline, such as elbows, front and rear valves, etc., which can monitor pressure changes in the pipeline in real time. When the pressure exceeds the safety threshold, the rupture disc will immediately rupture and relieve pressure, preventing the pipeline from fatigue and damage due to long-term overpressure, while reducing the environmental pollution of dust leakage and the health hazards of personnel.

In dust storage equipment, stainless steel rupture disk also plays an important role. In the process of storing dust in silos, storage tanks and other storage equipment, the internal pressure may increase due to spontaneous combustion of dust, moisture agglomeration, or excessive feeding speed. The rupture disc is installed on the top or side of the silo, which can rupture in time when the internal pressure of the equipment exceeds the safe range, release the pressure, and prevent the silo from exploding. For example, in the plastic particle storage silo, the stainless steel rupture disk can cope with the abnormal pressure caused by the accumulation of static electricity that may be generated by plastic dust, so that the silo is safe during storage.

In dust processing equipment, the application of stainless steel rupture disk has increased the scope of safety protection. During the processing process of pulverizers, mixers, screening machines and other equipment, sparks may be generated due to internal friction and impact of the equipment, which may cause dust explosions, resulting in a sharp increase in the internal pressure of the equipment. The rupture disc is installed on the chassis of these equipment, which can quickly rupture at the moment of the explosion, releasing the high-pressure gas and flame generated by the explosion, reducing the degree of damage to the equipment by the explosion and reducing the loss of accidents.

In short, stainless steel rupture disk has accurate blasting performance, good adaptability and reliable safety protection effect, and has been widely used in the dust industry in many aspects such as collection and treatment, transportation, storage, and processing. Stainless steel rupture disk can not only effectively prevent and reduce safety accidents caused by abnormal pressure, but also reduce equipment damage rates, reduce dust leakage, and provide technical support for the safe production of the dust industry.