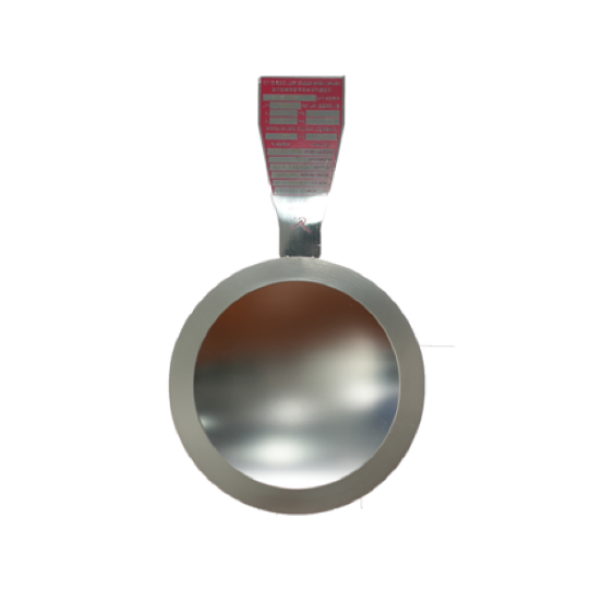

Arched metal blasting disc can explode at a specified temperature and pressure to release pressure. The rupture disc device consists of two parts: a rupture disc and a gripper. The rupture disc is an element for blasting and relieving pressure at the calibrated burst pressure and temperature, and the gripper is an auxiliary element for clamping the rupture disc in the appropriate part of the container. The rupture disc safety device has the advantages of simple structure, sensitivity, accuracy, no leakage, and strong discharge capacity. It can work reliably in viscous, high temperature, low temperature, and corrosive environments. It is an ideal safety device for ultra-high pressure containers. Arched metal blasting disc is an important safety device to prevent overpressure damage to pressure equipment. It is widely used in chemical, petroleum, light industry, metallurgy, nuclear power, dust removal and other industrial sectors.

The rupture disc device is a pressure relief device that cannot be closed repeatedly. It is activated by the static pressure at the inlet and releases the pressure through the rupture of the compressed diaphragm. Simply put, it is a disposable pressure relief device. At the set blasting temperature, when the pressure difference between the two sides of the rupture disc reaches a predetermined value, the arched metal blasting disc will break or fall off and release fluid.

The period of regular inspection of the rupture disc device can be specified according to the specific circumstances of the unit used, but the maximum period of regular inspection cannot exceed 1 year. Regular inspections should include checking the installation direction of the blasting disc device, verifying the blasting pressure and blasting temperature on the nameplate, checking the outer surface of the arched metal blasting disc for damage, corrosion and obvious deformation, checking the outer surface of the arched metal blasting disc for foreign matter adhesion and leakage, when the arched metal blasting disc is used in series with the safety valve, it is necessary to check the pressure indicator device between the blasting disc device and the safety valve, and also check the corrosion and smoothness of the discharge pipe. If a shut-off valve is installed between the blasting disc device and the equipment, it is necessary to check whether the shut-off valve is in In a fully open state, whether the lead seal is intact.

The replacement cycle of arched metal blasting disc should be reasonably determined according to specific influencing factors such as equipment use conditions, media properties, or design expected service life. Under normal circumstances, the replacement cycle of the blasting disc device is 2 to 3 years. For corrosive, toxic media and rupture disc devices used under harsh conditions, the replacement cycle should be shortened. The arched metal blasting disc has the wrong installation direction of the rupture disc device, the burst pressure and burst temperature on the nameplate do not meet the operating requirements, and the outer surface of the rupture disc is corroded, deformed, and foreign objects adhere and leak. It needs to be replaced immediately.