There is a close connection between temperature and the burst pressure of the bursting disc. Bursting discs are usually made of specific metals or composite materials, and the mechanical properties of these materials will change with temperature. When the temperature rises, the ductility of the material increases and the strength decreases, which means that under the same pressure, the bursting disc will be more prone to rupture, resulting in a decrease in the burst pressure. Conversely, when the temperature decreases, the material becomes more brittle and hard, and the burst pressure may increase. This nonlinear relationship between temperature and burst pressure requires precise calculations and considerations when designing and selecting bursting disc.

Taking the bursting disc of a metal material as an example, in a high temperature environment, the thermal movement of metal atoms intensifies, and the binding force between atoms weakens, resulting in a decrease in the yield strength of the material. If the impact of high temperature on material properties is not fully considered in the design, the originally set burst pressure may not be able to effectively protect the equipment, and the bursting disc will break early when the pressure does not reach the expected value, causing unnecessary downtime and economic losses. In a low-temperature environment, metal materials may experience cold brittleness, that is, the toughness of the material drops sharply. At this time, the burst pressure of the bursting disc will be significantly higher than the set value at room temperature. Once the internal pressure of the equipment rises abnormally, it may cause serious safety accidents because the bursting disc cannot break in time.

In order to cope with the complex influence of temperature on burst pressure, we have launched a series of high-performance and high-reliability bursting disc products through years of deep accumulation in the field of bursting disc research and development and production. Our R&D team adopts advanced technology, carefully selects and optimizes the material formula, so that the bursting disc can maintain stable performance in different temperature environments. At the same time, we accurately calculate the influence of temperature on the burst pressure and adjust the design parameters of the bursting disc so that the bursting disc can break accurately under various temperature conditions, providing reliable safety protection for the equipment.

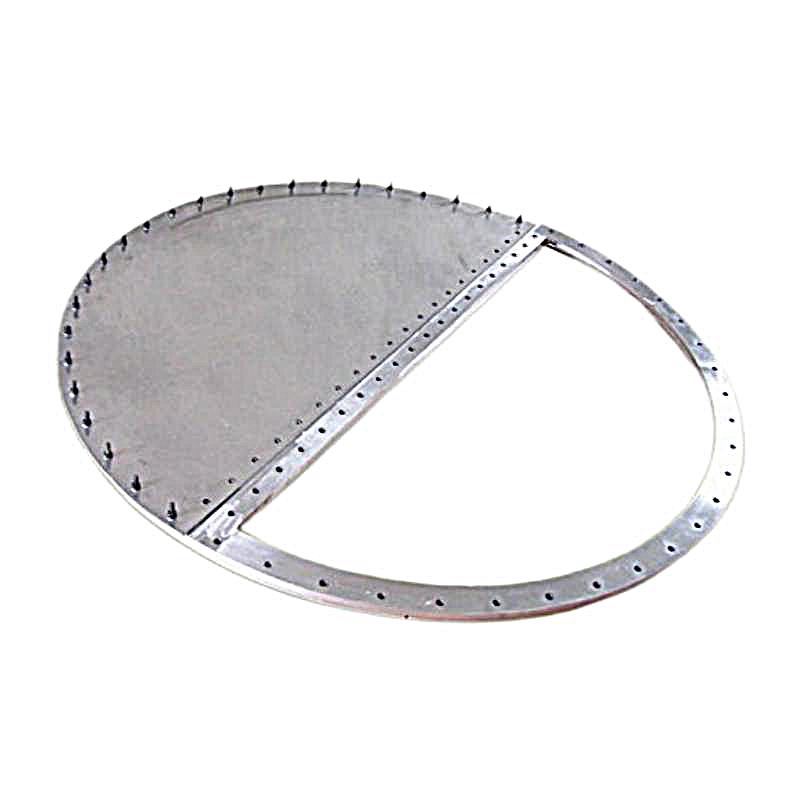

In terms of manufacturing technology, we strictly abide by international standards and norms, and use advanced processing equipment and testing methods to make every piece of bursting disc have excellent quality. Our products have undergone a large number of simulation experiments and actual working conditions tests, whether it is in a high-temperature chemical reactor or in a low-temperature liquefied gas storage tank and other extreme environments, they have shown excellent performance. In addition, we can also provide customers with customized solutions. According to the specific needs and application scenarios of customers, we can tailor the most suitable bursting disc products, so that the products and equipment are perfectly matched, and the safety protection function of bursting disc can be maximized.

For buyers, choosing our bursting disc is not only a choice of high quality and high reliability, but also a full range of professional services. We welcome buyers to contact us at any time, and look forward to establishing in-depth cooperative relations with you!