In industrial production, bursting discs for dust industry, as a pressure relief device to ensure the safety of equipment, the stability of performance is directly related to production safety. However, the particularity of the dust environment makes blasting discs often face some problems. In view of these common problems, we have summarized some targeted solutions that can improve the safety and protection effectiveness of rupture discs.

Dust adhesion is the primary factor that causes the performance failure of bursting discs for dust industry. To solve this problem, it is necessary to combine the prevention of adhesion and timely removal. In terms of preventing adhesion, rupture discs with anti-stick coatings such as polytetrafluoroethylene on the surface can be selected, and the low surface of the coating can be used to reduce dust adsorption. For high dust concentration scenarios, a filter or cyclone separator can be installed upstream of the rupture disc to intercept large particles of dust in advance and reduce the probability of attachment. Timely cleaning is also important. Enterprises should formulate a regular cleaning system and use compressed air to purify non-viscous dust. For viscous dust, an ultrasonic cleaning device can be used to remove the surface deposits of bursting discs for dust industry without disassembly.

In view of the malfunction or failure caused by pressure fluctuations, it is necessary to solve it from the two aspects of stabilizing the pressure source and choosing to adapt the rupture disc. In terms of process control, the pneumatic conveying system can be equipped with a pressure buffer tank to relieve the instantaneous pressure shock caused by fan start-stop and valve switching through volume compensation. The selection of bursting discs for dust industry needs to pay attention to fatigue resistance. For frequently fluctuating working conditions, priority is given to ductile materials such as austenitic stainless steel, which can reduce the risk of early blasting.

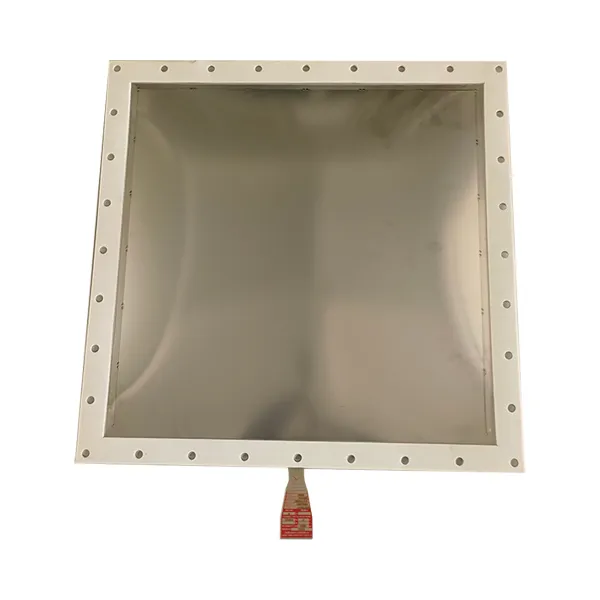

The normative nature of installation and maintenance is very important to the performance of bursting discs for dust industry, and it needs to be strengthened from both process and capability. The installation of bursting discs for dust industry requires strict inspection of the orientation of the raised surface, the diameter and pressure level of the bursting disc, and the flange connection surface needs to be cleaned of dust before installation. Temperature and pressure-resistant gaskets are used, and sealants are applied to assist in sealing if necessary. In addition, regular inspections of bursting discs for dust industry should be carried out, including visual inspection of the surface for dust accumulation and corrosion cracks, thickness changes should be detected with a thickness gauge, and dynamic monitoring can also be linked through the pressure sensor to alarm, and timely investigation when the pressure near the rupture disc fluctuates abnormally. In addition, bursting discs for dust industry must be replaced immediately after blasting. Temporary blocking is prohibited. Do not use a high-pressure water gun or a hard brush when cleaning. It is best to use a soft cloth dipped in neutral detergent to gently wipe to prevent scratches on the surface.

The above is the solution we summarized. Shenyang Xinguang Aerospace Safety Systems Co., Ltd. can provide customized rupture disc solutions to meet the special needs of different industries and customers. If you need it, please feel free to contact us!