When selecting a bursting disc, the following factors need to be considered:

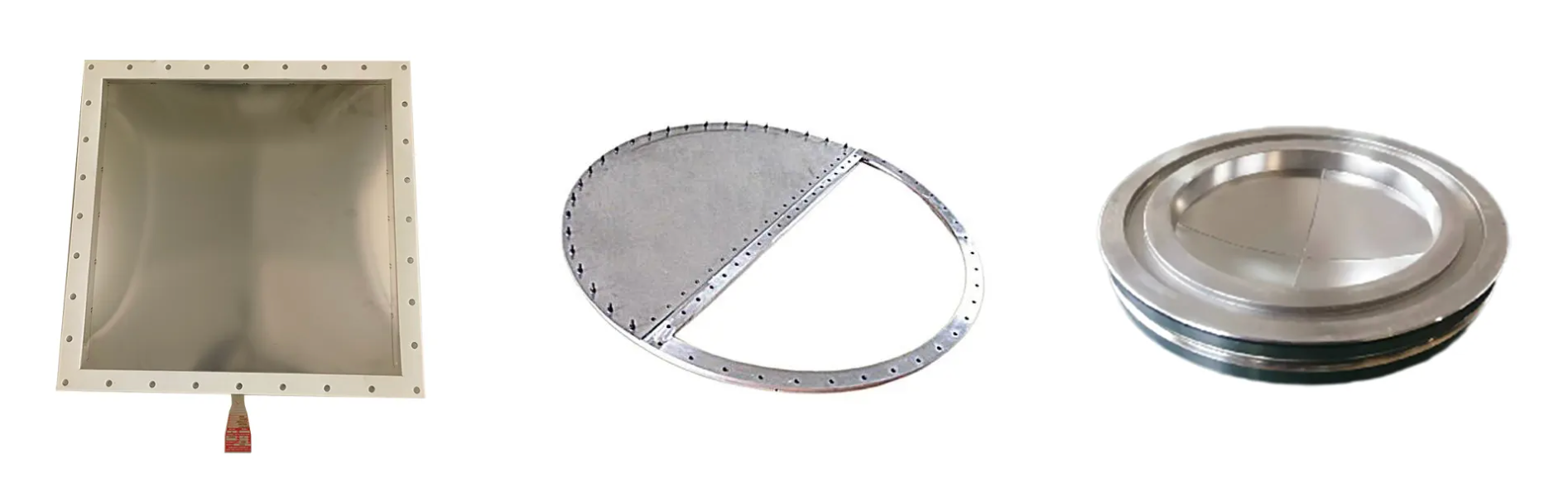

In high-pressure environments, it is recommended to select a positive arch bursting disc;

In low-pressure conditions, it is recommended to select a slotted bursting disc or a reverse arch bursting disc.

Depending on different industries, different factory environments, and different systems, there may be a vacuum state or the bursting disc needs to withstand back pressure. The corresponding back pressure bracket should be equipped to ensure system safety.

If there is cyclic pressure or pulse pressure in the system, a reverse arch bursting disc should be selected to adapt to this pressure change.

When considering temperature factors, it is necessary to evaluate the possible impact of high temperature on metal materials and sealing membranes to ensure that the selected bursting disc material can adapt to high-temperature working environments.

When used in front of a safety valve, there should be no fragments after the bursting disc explodes; when used for liquid media, a reverse arch bursting disc cannot be selected. Commonly used materials for making bursting discs are aluminum, nickel, stainless steel, or other alloys. For special purposes, gold, silver, titanium, etc. can be used.

When selecting a bursting disc, the following factors should also be considered:

Corrosion: For corrosion considerations, the bursting disc should be protected from being corroded by the medium. If there is a corrosive medium on site, a protective layer should be applied to the surface of the bursting disc or a lining such as polytetrafluoroethylene should be used to provide protection.

Using temperature: The fatigue resistance of the material needs to be considered, and it is necessary to ensure that the bursting disc can maintain its excellent performance even under high temperature conditions.

Economical efficiency: The low-cost material should be selected on the basis of ensuring that the bursting disc meets all performance requirements.

For over 60 years, Xinguang Aerospace has adhered to high standards and strict requirements, meticulously controlling design plans and material selection. The company now holds more than 30 independent intellectual property rights and has successfully localized burst disc devices for numerous domestic enterprises. It has also participated in the drafting and formulation of multiple national and industry standards, including "Burst Discs and Burst Disc Safety Devices" and "Safety Technical Supervision Regulations for Burst Disc Devices." In 2022, the company achieved CE system certification in Europe and ASME UD system certification. Its diverse range of burst disc devices is widely used in industries such as petrochemicals, pharmaceuticals, metallurgy, power generation, environmental protection, storage and transportation, cryogenics, fire protection, long tube trailers, nuclear power, and military applications, earning widespread recognition and acclaim from users.