Introduction of reverse disc holder:

The Holder for YE reverse disc is a standard holder designed specifically for reverse arch rupture discs. The holder for YE reverse disc can accurately position the rupture disc and provide structural support to achieve the best sealing effect and keep the discharge area in the system stable. The holder for YF reverse disc adopts a scientific design to make the structure more solid. Our reverse acting rupture disc holders are made of high-strength metal materials, and the pressure resistance and sealing performance have been improved, so that the rupture disc can still act quickly, accurately and safely under overpressure.

Features of rupture disc holder for reverse acting discs:

1. The reverse disc holder is designed with a special positioning pin hole on the clamping surface, which allows the rupture disc to be installed in a unique direction, making the force more uniform.

2. The Holder for YF reverse disc increases the entrance height to form an effective "protective space" inside, effectively preventing the rupture disc from being accidentally damaged during installation and operation, and extending the service life of the holder for YF reverse disc.

3. The reverse acting rupture discs holders adopt an all-metal sealing structure, which can ensure the sealing of the holder for YF reverse disc under high pressure environment, and is more suitable for use in high temperature, high pressure or corrosive media.

4. The reverse disc holder comes with a nameplate arrow mark when it leaves the factory, which can indicate the pressure relief direction of the medium. Even in complex working conditions, the Holder for YF reverse disc can quickly identify the installation direction, improving the efficiency and safety of maintenance.

Uses of holder for YF reverse disc:

Reverse acting rupture discs holders are suitable for use with YCS、YCT、YCD、YE、YF type reverse arch rupture discs, and are widely used in various high-pressure, medium-pressure, vacuum and other industrial systems. Our rupture disc holder for reverse acting discs is suitable for the installation of rupture discs in equipment such as reactors, towers, and heat exchangers, and can effectively resist the erosion of high temperature, corrosive media and variable pressure. In boilers, hydropower, and gas power generation systems, the reverse disc holder can withstand the structural impact caused by high thermal expansion and contraction and frequent start and stop. Similarly, our holder for YE reverse disc is also suitable for complex working conditions such as natural gas compression devices, separators, and oilfield wellhead equipment, which can effectively prevent the leakage of combustible gases and improve the safety factor. In marine pressure chambers and other occasions, the use of reverse acting rupture discs holders and reverse arch rupture discs can adapt to extreme working conditions such as high salt spray and high vibration.

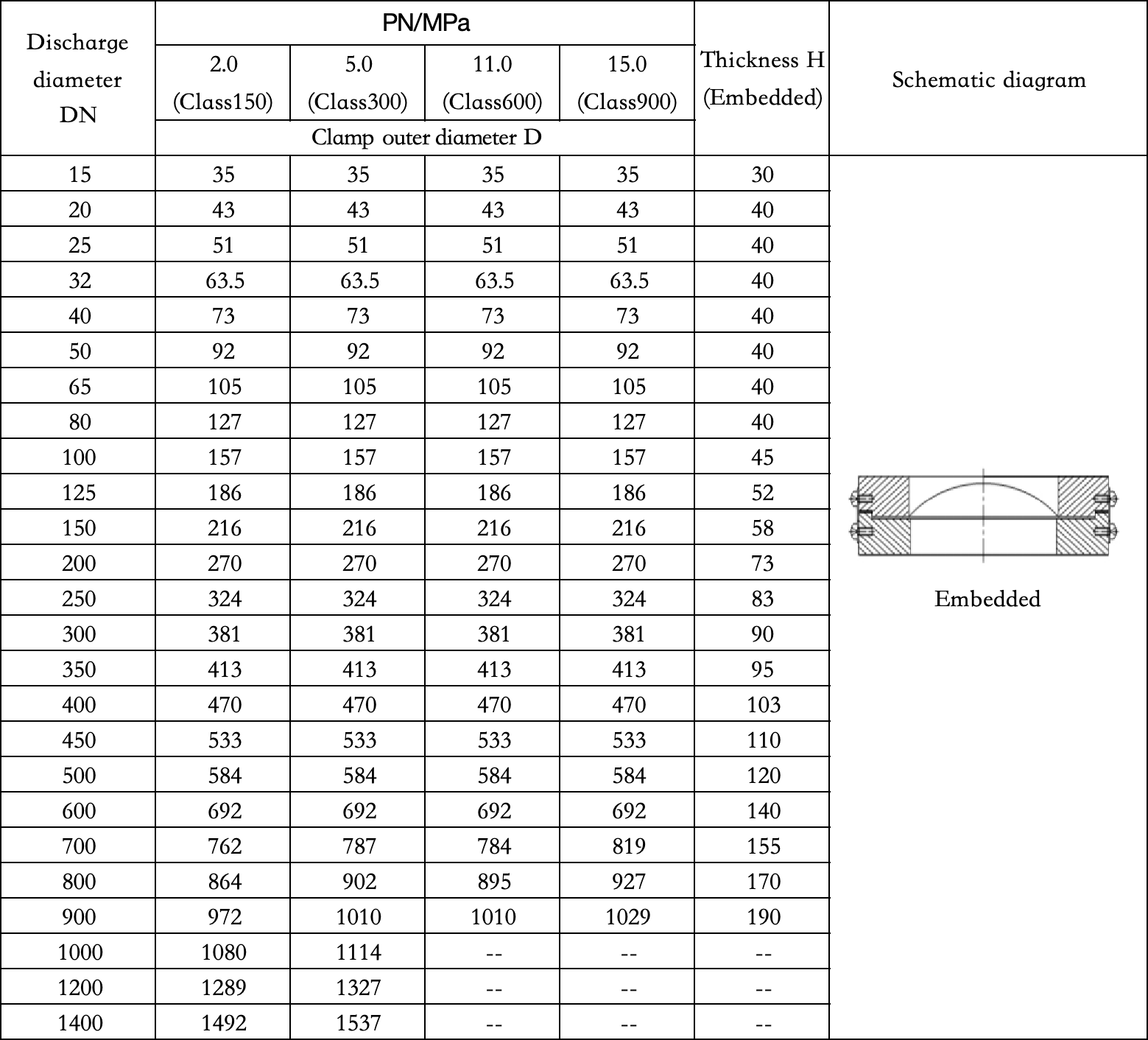

Parameters of Reverse acting rupture discs holders:

mm

Working principle of rupture disc holder for reverse acting discs:

During the installation of reverse disc holder, the rupture disc is clamped between the upper cover and the base of the Holder for YF reverse disc, and a strong clamping force is formed by bolt locking. The positioning pin of the holder for YF reverse disc ensures that the rupture disc is correctly placed to avoid the wrong direction, and keeps the center of the rupture disc aligned with the pressure relief channel to prevent the system from bursting and failing. When overpressure occurs during the operation of the reverse acting rupture discs holders, the pressure is first transmitted to the rupture disc, which will quickly open and release the pressure according to the set pressure. The guide structure and sealing structure of the rupture disc holder for reverse acting discs will guide the medium to safely release pressure in the designed direction, and suppress bypass leakage through metal sealing to ensure that the pressure relief path is concentrated and there is no mistake.

How to use the reverse disc holder:

Before installation, ensure that the holder for YE reverse disc and the matching rupture disc model match, and confirm the medium pressure relief direction according to the arrow on the nameplate. During installation, place the rupture disc on the base of the holder for YE reverse disc and align the positioning pin. Then press the cover lightly and tighten the bolts evenly diagonally to ensure consistent clamping force. After installation, the reverse acting rupture discs holders should be checked for tightness. During the operation of the rupture disc holder for reverse acting discs, the connection status of the reverse disc holder and the surrounding area should be checked regularly for leakage. If any problems are found, replace the reverse disc holder in time.

FAQ:

1. Can the holder for YE reverse disc be installed on a vertical pipeline?

Our holder for YE reverse disc has a very stable structure and can adapt to horizontal, vertical and inclined installation.

2. Will the reverse disc holder loosen due to pressure shock?

The holder for YF reverse disc is fastened with high-strength metal bolts, which can withstand pressure far higher than the maximum working pressure of the system and can ensure stable operation.

3. Is the reverse disc holder suitable for corrosive media systems?

Yes.

About us:

Xinguang has a complete quality management system and passed the ISO9001:2000 quality management system certification in 2001. The products are used in petrochemical, petroleum, chemical, pharmaceutical, food, steel, electricity, environmental protection, natural gas, boiler, air conditioning, tank truck and other industries to produce various types of bursting disc safety devices, and have won the titles of national, ministerial, provincial, high-quality products and national user satisfaction products for many times.