As an overpressure safety discharge device, bursting discs for nuclear power can directly affect the operation safety of core equipment such as nuclear reactors, voltage regulators, and steam generators. However, due to the particularities of nuclear power systems such as high temperature, high pressure, high radiation, highly corrosive media and complex working conditions, bursting discs for nuclear power often faces some problems in the process of use. Today I will introduce you through this article.

The installation quality of the rupture disc will directly affect the performance. The precision of the nuclear power system requires higher installation requirements. In this regard, the common problems of bursting discs for nuclear power are the wrong installation direction, and the rupture disc has a clear positive and negative direction. If it is installed in reverse, it will cause the burst pressure to deviate significantly from the design value and even fail to explode.

In nuclear power systems, bursting discs for nuclear power are often connected in series with safety valves. If the distance between the two is too close, the air flow impact when the safety valve is opened will cause the force of the rupture disc to mutate, causing unexpected rupture. If the pressure monitoring point is not set in the series pipeline, the leakage of the rupture disc cannot be found in time, which may cause the safety valve to malfunction.

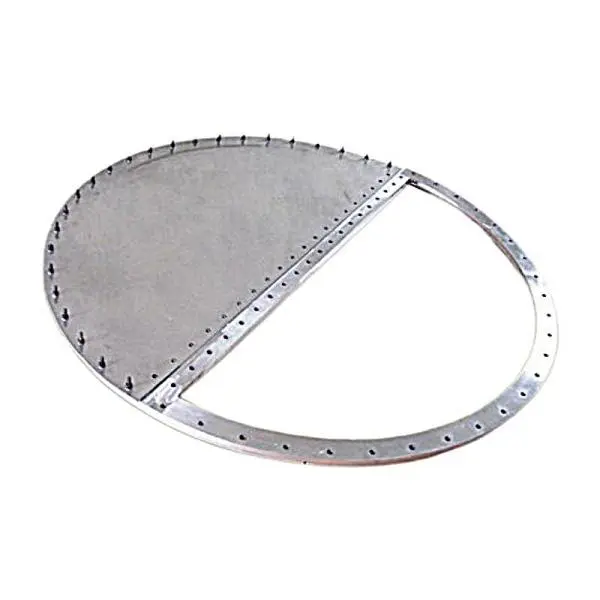

Bursting discs for nuclear power are connected to the pipe flange through a gripper. If there are scratches, oil stains on the sealing surface, or uneven torque of the flange bolts during installation, it will cause micro-leakage of the medium. For radioactive media systems, micro-leakage will not only cause the dose to exceed the standard, but also cause the medium to erode the edge of the rupture disc, resulting in a decrease in strength and causing early blasting. In addition, the gap between the gripper and the rupture disc is too large, which can cause the rupture disc to vibrate when the pressure fluctuates, forming fatigue cracks.

The strong radiation, high temperature, high pressure and corrosive media in the nuclear power environment will accelerate the deterioration of the material of bursting discs for nuclear power, resulting in performance attenuation. Specific conditions include radiation embrittlement. In the high-energy radiation environment near the reactor, metal materials may produce lattice defects due to irradiation, resulting in decreased material toughness and increased brittleness. The brittle rupture disc may break directly without plastic deformation under pressure load, and the deviation of the burst pressure increases significantly, and the release behavior cannot be predicted.

Periodic fluctuations in pressure in nuclear power systems will cause bursting discs for nuclear power to withstand alternating loads. If the number of cycles exceeds the fatigue limit of the material, fatigue cracks will occur in weak parts. After the crack spreads to a certain extent, the rupture disc will suddenly rupture under operating conditions far below the design pressure.

In short, the use of bursting discs for nuclear power is essentially due to the high parameters, strong radiation and multi-media corrosion of the application environment. To solve these problems, we need to carefully consider the particularity of the nuclear power environment and improve the environmental adaptability of the rupture disc itself. Our company can provide you with customized solutions to produce rupture discs that meet your requirements and standards and can be stably discharged under extreme working conditions. If you need it, please feel free to contact us!