Introduction of Bursting discs for energy storage industry:

Rupture disc for dust medium is a safety device commonly used in industrial equipment. It is mainly used to automatically rupture and release pressure when the internal pressure of the equipment increases abnormally, so as to prevent the equipment from exploding or being seriously damaged due to overpressure, thereby protecting personnel safety and equipment integrity. Rupture disc for dust medium has a simple structure, quick response, and is suitable for a variety of media and working conditions. It is widely used in chemical, petroleum, pharmaceutical and other industries.

Structure and principle of Bursting discs for energy storage industry:

Composition of PF type rupture disc:

PF type rupture disc is a flat rupture disc composed of a flat diaphragm with seams, a sealing gasket, an outlet frame and a heat preservation cover. The surface of PF type rupture disc is pre-engraved with slits to control the rupture direction and shape.

Working principle of PF type rupture disc:

When the internal pressure of the equipment reaches or exceeds the preset value, the PF type rupture disc will quickly rupture along the slits to form a pressure relief channel, so that the high-pressure fluid can be quickly discharged, thereby reducing the internal pressure of the equipment to a safe range.

Features of Bursting discs for energy storage industry:

1. Composite flat seat rupture disc is suitable for the protection of normal pressure systems.

2. Composite flat seat rupture disc is suitable for flammable and explosive gases and dust media.

3. The applicable temperature of Composite flat seat rupture disc is: -40℃~200℃.

4. Composite flat seat rupture disc has a fast response speed and can respond quickly in a short time.

Structural dimensions of PF type rupture disc:

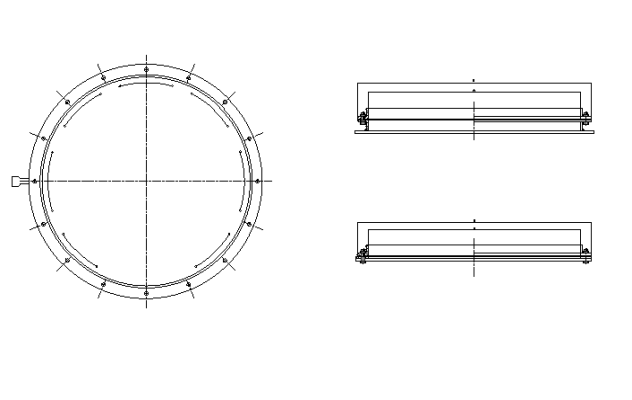

Circular shape:

PF circular structure size table:

Note:

Special specifications and sizes can be negotiated separately.

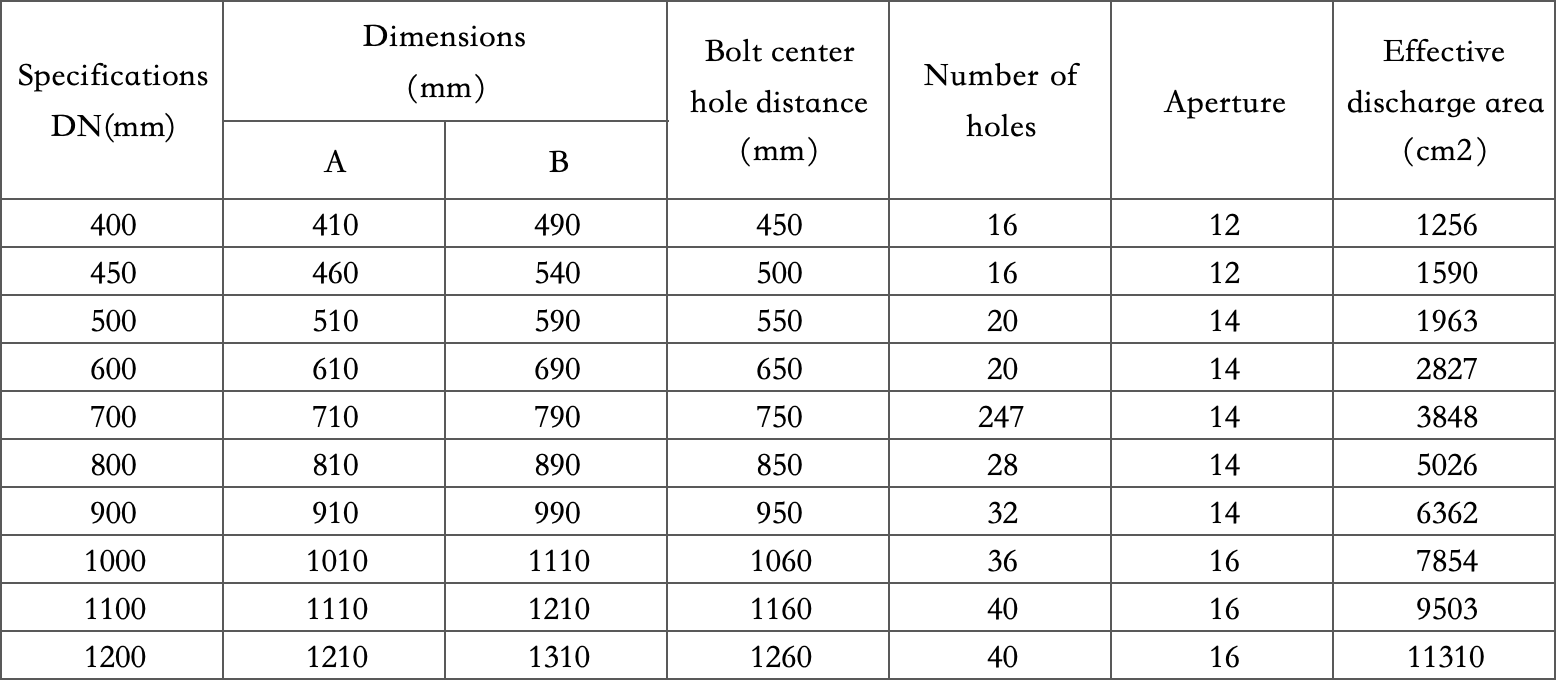

Rectangular pattern:

Note: Special specifications can be negotiated.

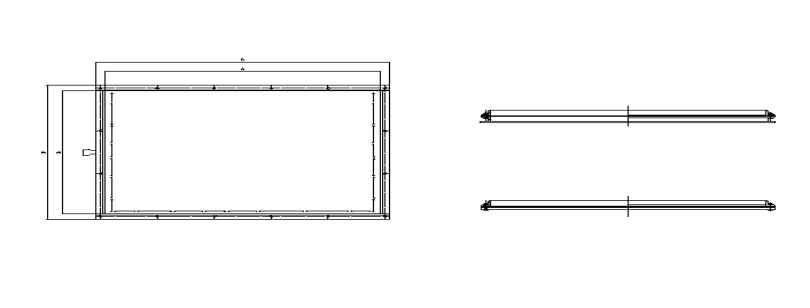

PF type rupture disc adapter holder:

Application scenarios of Bursting discs for energy storage industry:

Rupture disc for dust medium is widely used in the following scenarios:

Chemical equipment: such as reactors, storage tanks, etc., to prevent abnormal pressure increase caused by chemical reactions.

Petroleum equipment: such as oil tanks, oil pipelines, etc., to prevent overpressure caused by temperature changes or operational errors.

Pharmaceutical equipment: such as fermentation tanks, extraction tanks, etc., to ensure the safety of the production process.

Installation and maintenance precautions of PF type rupture disc:

Installation location: Rupture disk for standard pressure should be installed at the highest pressure point of the equipment or the area where pressure is most likely to accumulate.

Installation direction: Ensure that the discharge arrow direction of Rupture disk for standard pressure is correct.

Clamping force: When installing Rupture disk for standard pressure, ensure that the sealing surface of the clamp and flange are completely aligned. The tightening of the bolts should be symmetrical, alternating, and loaded one by one. Use a torque wrench to tighten according to the specified torque value.

Regular inspection: Although the Rupture disk for standard pressure requires almost no maintenance, it is still necessary to check the condition of the Rupture disk for standard pressure during regular inspection of the equipment to check for damage or corrosion.

About us:

All Rupture disc holders for positive acting discs need to be visually inspected before leaving the factory to ensure quality of Forward disc holder and no defects.

All Forward disc holder are tested in the factory to ensure performance under specified pressure and temperature.