Introduction of Standard 30° seat rupture disc:

The bursting pressure of the product is determined by the tensile strength of the material of the rupture disc itself. The system pressure acts on the concave surface of the rupture disc arch shell. When overpressure occurs, the product is stretched, and the wall thickness of the arch shell is reduced to rupture, thereby releasing pressure.

Advantages of Standard 30° seat rupture disc:

1. Standard forward acting rupture disc is suitable for both gas and liquid media.

2. Standard forward acting rupture disc is suitable for high temperature and high pressure working environment.

3. The maximum working pressure of Standard forward acting rupture disc can reach 70% of the minimum allowable bursting pressure.

4. Standard 30° seat rupture disc has fragments after rupture and must not be used in series with safety valve.

5. The bracket can withstand back pressure.

6. The pressure range of Standard 30° seat rupture disc during use is greatly limited by the tensile strength of the material itself.

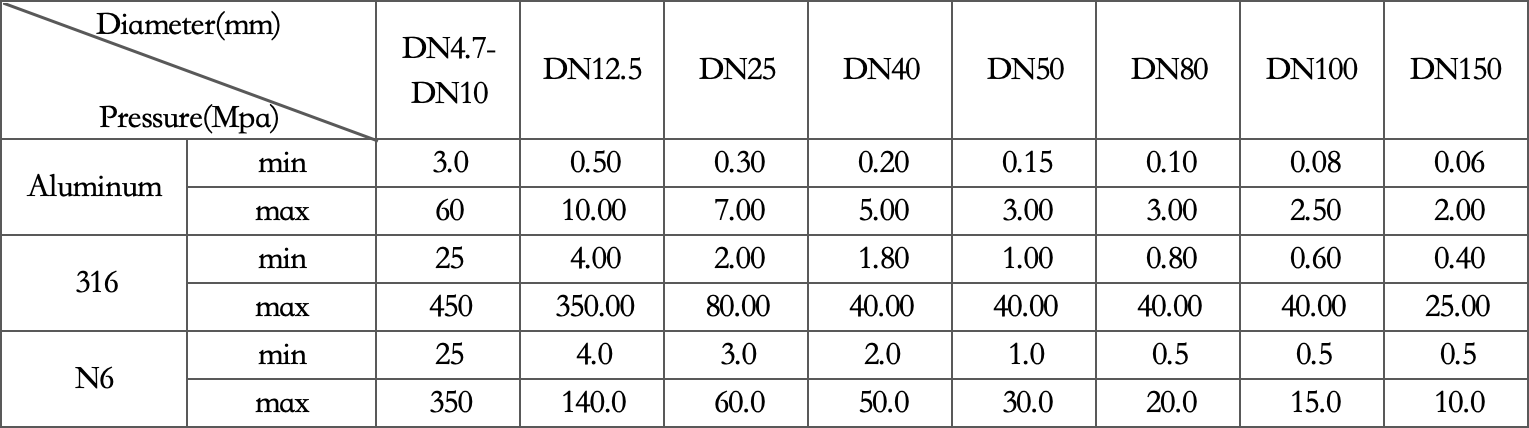

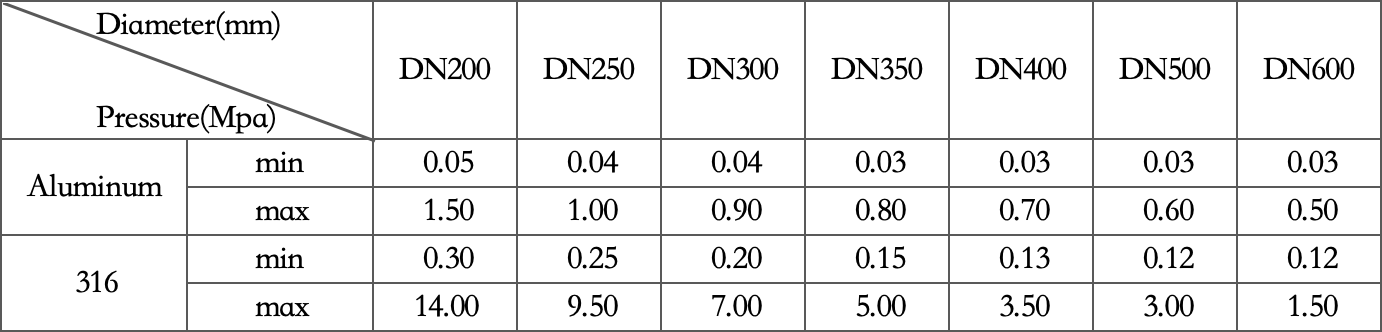

Specifications of Standard 30° seat rupture disc:

Processable pressure range:

Minimum/maximum bursting pressure at 22°.

Unit: Mpa

Notes:

1. The above data is for reference only. Due to material limitations, the actual processing value may be different from the table. Please contact the customer service team for consultation.

2. If the Pressure relief rupture discs are made of other materials, please refer to this data sheet. For special materials, please consult the manufacturer to ensure delivery time.

3. If fluorine coating or polytetrafluoroethylene coating is required, the maximum operating temperature is 260℃.

Application of Pressure relief rupture discs:

Pressure relief rupture discs are suitable for any occasion.

LP Reverse acting rupture disc adapter holder:

Why choose our Positive arch ordinary type rupture discs?

1. Independent R&D and leading technology:

We have an independent R&D team and laboratory. All bursting disc products are independently developed by us from design, material selection, process to testing, without relying on outsourcing or OEM.

We invest a lot of resources every year to upgrade and develop products, such as special products suitable for extreme working conditions.

2. Strong production capacity and stable and reliable delivery:

Own factories and precision processing equipment: We are equipped with advanced CNC equipment to ensure the accuracy and consistency of products.

Fully implement the international quality management system, and each product undergoes multiple tests.

3. More stable safety performance:

The product has fast response and high precision, especially suitable for working conditions that require high safety protection. Some models have safety designs such as anti-fatigue to meet the long-term use requirements under extreme working conditions.

4. Perfect customer service and technical support:

We are equipped with experienced engineers to provide customers with full-process support such as selection suggestions and usage guides. For after-sales needs, we respond within 24 hours and reply to customers as soon as possible.