Introduction of Composite flat seat rupture disc:

LF bursting disc is a combination of a bursting membrane, a bracket and a sealing membrane. The bursting membrane and the bracket arch shell are machined with seams and holes to reduce strength. When the protected system is overpressured, the bursting membrane and bracket of the LF bursting disc rupture along the seams and holes, thereby releasing pressure.

Advantages of Composite flat seat rupture disc:

1. The maximum working pressure of domed bursting disc can reach 80% of the minimum allowable bursting pressure.

2. Domed bursting disc is suitable for gas or liquid media.

3. Domed bursting disc will produce fragments after blasting during field operation, so it cannot be used in series with safety valve.

4. Domed bursting disc with bracket can withstand vacuum back pressure.

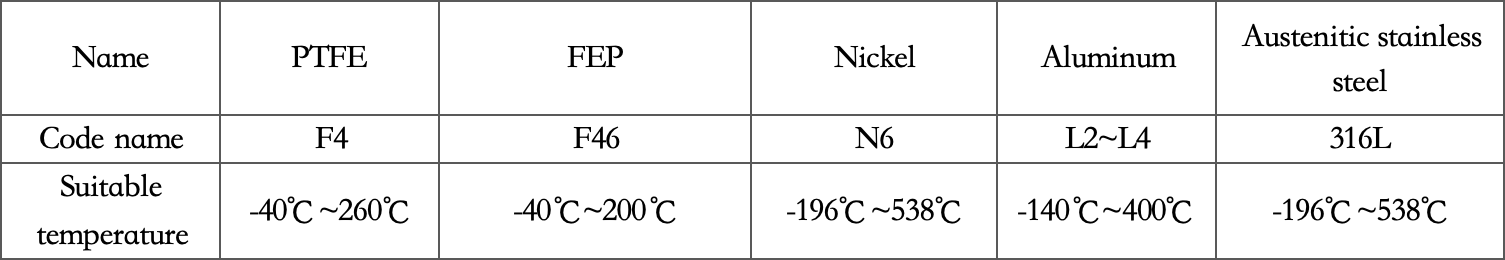

5. The maximum applicable temperature of LF bursting disc is determined by the sealing film material. (See the table below for sealing film material and its applicable temperature)

Specifications of LF bursting disc:

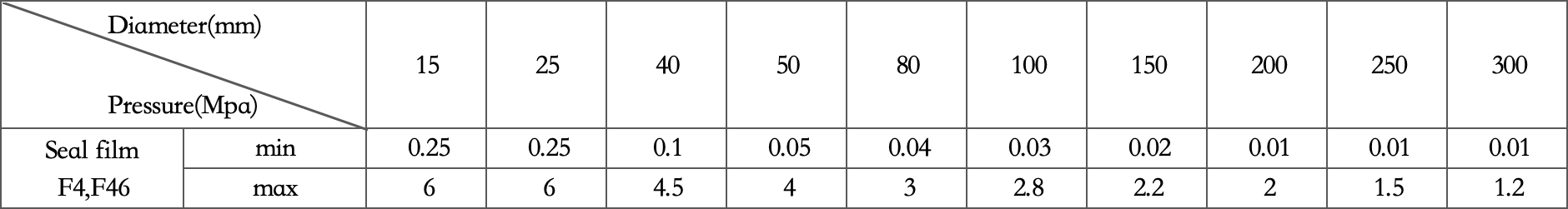

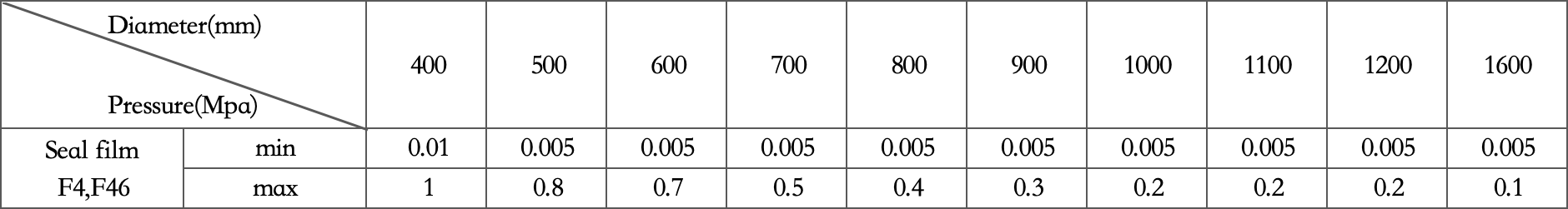

Processable Pressure Range:

Minimum/Maximum Burst Pressure at 22°.

Unit: Mpa

Notes:

1. The above data is for reference only. If the actual design is different from the data in the table, please consult the manufacturer.

2. The above parameters are for the material of the bursting disc is austenitic stainless steel.

3. For other materials, please refer to this parameter table. For special materials, please consult the manufacturer to ensure the delivery date.

Application of Composite type rupture disc:

The Composite type rupture disc is suitable for any occasion.

FAQ:

Q1: Are you a manufacturer? Can you customize LF bursting disc?

A1: Yes, we are a professional bursting disc manufacturer with independent factories and R&D teams. LF bursting disc supports customized parameters such as bursting pressure, caliber, material, etc. to meet the needs of different working conditions.

Q2: What materials are available for your Composite type rupture disc?

A2: We have a variety of materials to choose from, and we will recommend the most suitable products to customers based on the characteristics of the media and actual working conditions.

Q3: How long is your delivery cycle?

A3: Conventional models are in stock, and customized products depend on specific requirements.

Q4: Can you supply bursting disc holders?

A4: Yes. We also produce and provide special holders that match domed bursting discs to keep the system highly sealed and easy to install.

Domed bursting disc adapter holder:

High-end equipment, fine processing:

We have a modern workshop, and the automated precision processing equipment runs at high speed to ensure the precision of each product. The company has specially introduced advanced testing instruments to conduct strict pressure testing, sealing testing and fatigue testing on the Composite type rupture disc, so that the products are still stable, reliable and durable in extreme environments.