Introduction of the reverse buckling cross-scored bursting disc:

The reverse buckling bursting disc is a passive safety device for safe pressure relief of low-pressure to medium-pressure equipment. The precision scored reverse rupture disc can be used in chemical, petrochemical, pharmaceutical, food processing, energy, environmental protection and other industries. The core structure of the precision cut reverse rupture disc is composed of a reverse arched metal sheet with a "cross" groove, which is usually used with a special clamp. The reverse arch with slotted rupture disc will maintain a closed state when the system is operating normally, but once the medium pressure exceeds the rated burst value, the rupture disc will quickly lose stability and flip over, rupture along the "cross" groove, and release pressure. The reverse buckling cross-scored bursting disc has undergone a precise heat treatment process and can maintain stable operation.

Features of the reverse buckling bursting disc:

1. Our precision scored reverse rupture the disc will not produce fragments when it explodes, and can be used in series with the safety valve to improve the safety of the system.

2. Precision cut reverse rupture disc is suitable for system environments with pulsating pressure and has strong anti-fatigue performance.

3. Reverse arch with slotted rupture disc can withstand the complete vacuum state of the system, which simplifies the installation structure and saves the cost of accessories.

4. Reverse buckling cross-scored bursting disc can be used for pressure relief protection of gas media, especially dangerous media such as hydrogen, nitrogen, and oxygen. The maximum working pressure of the reverse buckling bursting disc can reach 90% of the minimum bursting pressure and can withstand high-load operation.

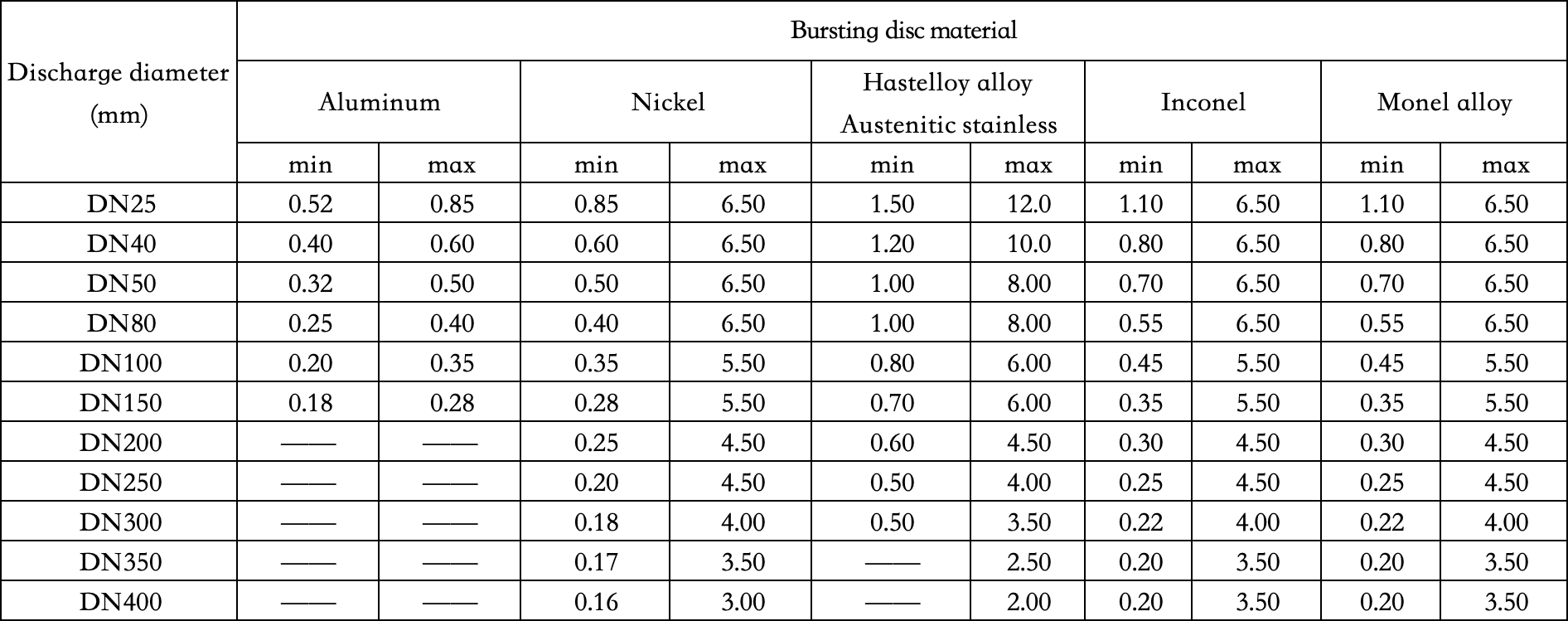

Specifications of Precision Scored Reverse Rupture Disc:

Processable pressure range:

Min./max. bursting pressure at 22°.

Unit: Mpa

Note:

1. The values in the table are for reference only. If the actual values are different, please consult the manufacturer.

2. If polytetrafluoroethylene or polypropylene is required, please pay attention to its operating temperature.

3. The selection of tantalum materials should be consulted with the manufacturer.

Application of reverse buckling cross-scored bursting disc:

Reverse buckling bursting disc can be used in natural gas separators, desulfurization towers, hydrogenation reactors and other equipment in the petrochemical industry to prevent the danger caused by system overpressure. Precision scored reverse rupture disc will not produce particulate pollution, so it can be used in fermentation tanks, distillation units and other equipment in the pharmaceutical industry. Our precision cut reverse rupture disc is also widely used in dairy tanks, beer tanks, carbon dioxide systems, etc.

Working principle of reverse arch with slotted rupture disc:

Under normal working conditions, reverse buckling cross-scored bursting disc is an arch structure that can withstand positive or negative pressure loads in the system. When the system pressure rises slowly or instantly and reaches the bursting pressure, the reverse arch surface begins to flip, releasing the internal medium and quickly releasing pressure to protect the downstream equipment or the entire system. Reverse buckling bursting disc can keep the rupture direction of the bursting disc consistent, and can also avoid the splash of fragments, improving overall safety.

FAQ:

1. Can the precision scored reverse rupture disc be used with all clamps?

Not completely universal.

2. Can the precision cut reverse rupture disc be used under vacuum conditions?

Reverse arch with slotted rupture disc can withstand a complete vacuum state.

3. Is the reverse buckling cross-scored bursting disc prone to fatigue?

Our reverse buckling bursting disc maintains good anti-fatigue performance within the compliant pressure range.

YCS type rupture disc adapter holder:

About us:

Shenyang Xingguang Aerospace Safety System Co., Ltd. is the first professional manufacturer of bursting disc safety devices integrating design, manufacturing, sales and service after the founding of New China. It was born in 1959 in the cradle of New China's aerospace power plant, Aerospace Xingguang Group. In 1986, it obtained the "Burst Disc Device System License" issued by the Ministry of Labor. In 2000, it was recognized as a high-tech enterprise by the Provincial Department of Science and Technology. With strong technical strength, rigorous quality assurance system and excellent equipment, the company has grown into a well-known brand in the field of safety systems.