Introduction of reverse buckling rupture disk:

The main structure of YD type rupture disc is composed of a piece of special metal, which can provide precise overpressure protection for medium and low pressure safety relief system. The metal sheet of reverse buckling rupture disc is prefabricated with c-shaped precision grooves during the manufacturing process, and combined with the reinforcement ring to form a reverse arch structure. When the enhanced reverse buckling rupture disc is working in the system, the pressure-bearing side of the rupture disc faces the concave surface, and is sealed and positioned by the clamp. YD type rupture disc can be used in gas medium system, can also adapt to all liquid medium equipment, and can withstand complete vacuum state, with strong adaptability.

Features of reverse acting serrated bursting disc:

1. The biggest feature of our YD type rupture disc is "fragment-free bursting". The ycd type uses a c-shaped ring groove design to enable the reverse buckling rupture disk to crack along a fixed path during bursting, without splashing or dropping fragments, and the use process is very safe.

2. Our reverse buckling rupture disk can work normally in an environment with frequent fluctuations or pulsating pressures, effectively extending the service life.

3. The reverse acting serrated bursting disc can withstand a complete vacuum state, so it can switch between vacuum and high pressure repeatedly, and has strong adaptability.

Use of YD type rupture disc:

Our reverse buckling rupture disc is suitable for use in various industries. In the chemical industry, it can provide overpressure protection for equipment such as reactors, storage tanks, condensers, separators, etc., especially for chemical systems with strong corrosion, high sealing or gas-liquid mixing. Reverse buckling rupture disk can quickly adapt to the needs of high-pressure discharge and protect the safety of equipment and personnel. The reverse acting serrated bursting disc we produce can be used in fermentation tanks, extractors, liquid delivery systems and other occasions. Its fragment-free design can meet the requirements of clean production environments. In addition, our YD type rupture disc is also suitable for many application scenarios.

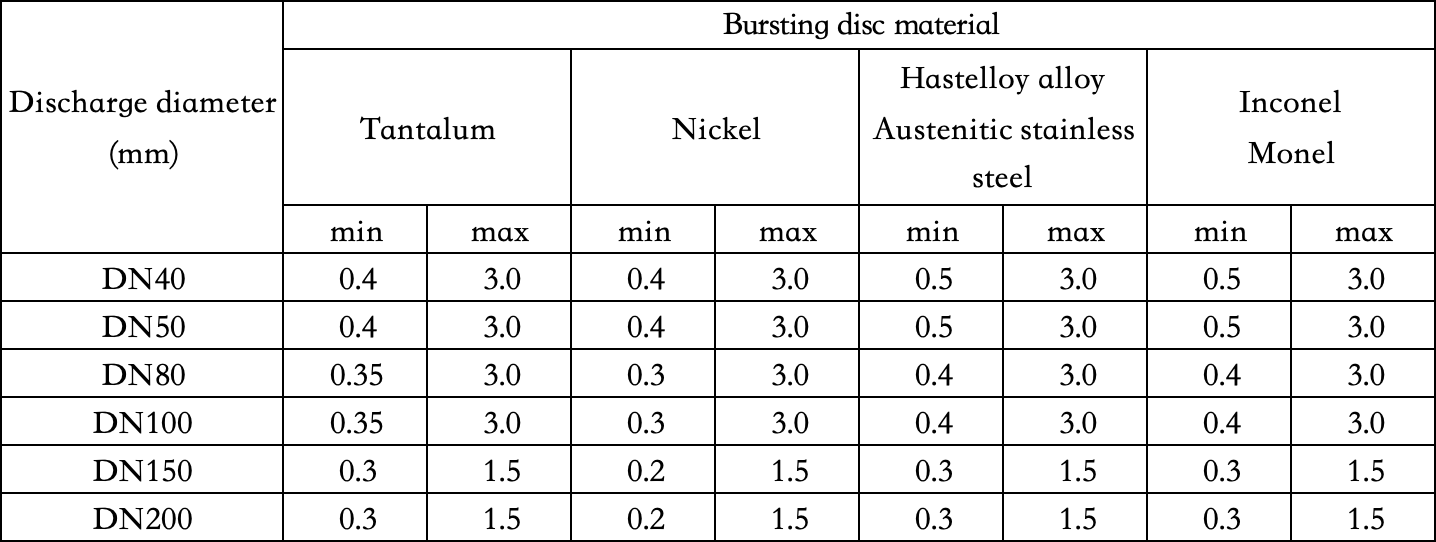

Specifications of YD type rupture disc:

Processable pressure range:

Min./max. bursting pressure at 22° .

Unit: Mpa

Note:

1. The values in the table are for reference only. If the actual values are different, please consult the manufacturer.

2. If polytetrafluoroethylene or polypropylene is required, please pay attention to its operating temperature.

3. The material of the special bracket is generally austenitic stainless steel.

4. The selection of tantalum materials should be consulted with the manufacturer.

Working principle of reverse buckling rupture disc:

When the internal pressure of the system of the enhanced reverse buckling rupture disc rises to close to the bursting point, the rupture disc will first lose stability and flip over, and then the metal sheet will begin to break along the prefabricated c-shaped ring groove. Because the design accuracy of the notch is high, the crack will quickly expand along the designed path, and finally break completely, completely opening the pressure relief channel.

FAQ:

1. What is the maximum working pressure of the reverse acting serrated bursting disc?

The maximum working pressure of the reverse acting serrated bursting disc can reach 90% of its minimum allowable bursting pressure.

2. Will the YD type rupture disc produce metal fragments?

No.

3. Will the reverse buckling rupture disk be installed upside down?

No. Our enhanced reverse buckling rupture disc is equipped with a positioning pin hole. When it is matched with the clamp, it can only be installed in the correct direction, and there will be no reverse installation problem.

YCD type rupture disc adapter holder:

About us:

Xinguang was founded in 1959 and has a 6,000 square meter production base. It has more than 30 independent intellectual property rights. Its products are used in petrochemical, petroleum, chemical, pharmaceutical, food, steel, electricity, environmental protection, natural gas, boilers, air conditioning, tank trucks and other industries. It produces various types of bursting disc safety devices.